Create Your Parts

- Share

In this section you will know more about our plastic injection molding service and discover information directly related to injection mold processes .

Choose Material

A selection of the most commonly used custom thermoforming materials are listed below.

ABS (Acrylonitrile Butadiene Styrene): Very common material. Good stiffness and impact strength. Available in a wide variety of colors and several textures. Available in UL94-V0 grades (Flame Retardant).

ACRYLIC (PMMA – Polymethyl Methacrylate, Plexiglass): Water clear and abrasion resistant material. Easily fabricated. Available in impact modified grades. Many colors available.

HDPE (High Density Polyethylene): Excellent impact and chemical resistance. Good cold temperature properties. Dimensionally not as stable as other materials.

HIPS (High Impact Polystyrene): Low cost, forms easily. Available in many colors. More brittle than ABS.

KYDEX (PMMA / PVC blend): Good general-purpose material, offering excellent impact and chemical resistance in a highly cosmetic sheet. Most grades are flame retardant to UL94-V0. Available in many colors and textures.

PC (Polycarbonate): Very high impact strength. Clear. High temperature resistance.

PEI (Polyetherimide, Ultem): Very high temperature grade material. Autoclavable. Natural amber color.

PETG (Polyethylene Terephthalate Glycol): Clear, with excellent impact strength. Forms well.

PP (Polypropylene): Excellent chemical resistance. Rigid, with very good impact strength. Good at higher temperatures. But dimensionally not as stable as other materials, similar to HDPE.

PVC (Polyvinyl Chloride): Rigid material. Very good impact strength. Flame retardant. Limited availability.

TPO (Thermoplastic Polyolefin): Outstanding impact properties. Available with a high gloss finish. Good for outdoors applications. More difficult to form, especially deep draw shapes.

Other specialty materials are available, just contact us.

Equipment

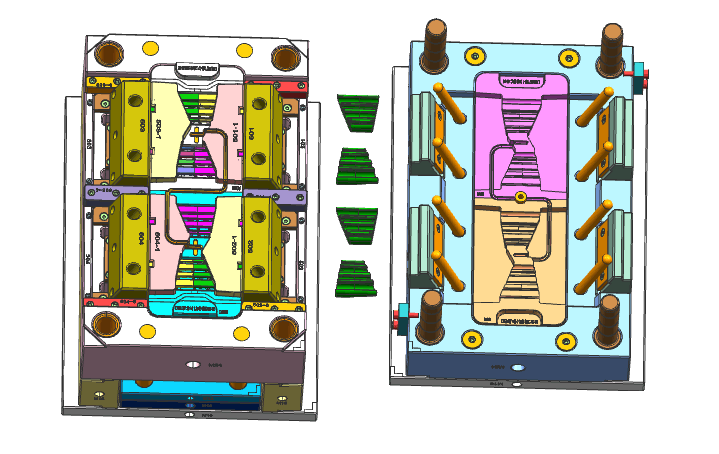

Injection Molds Machinery

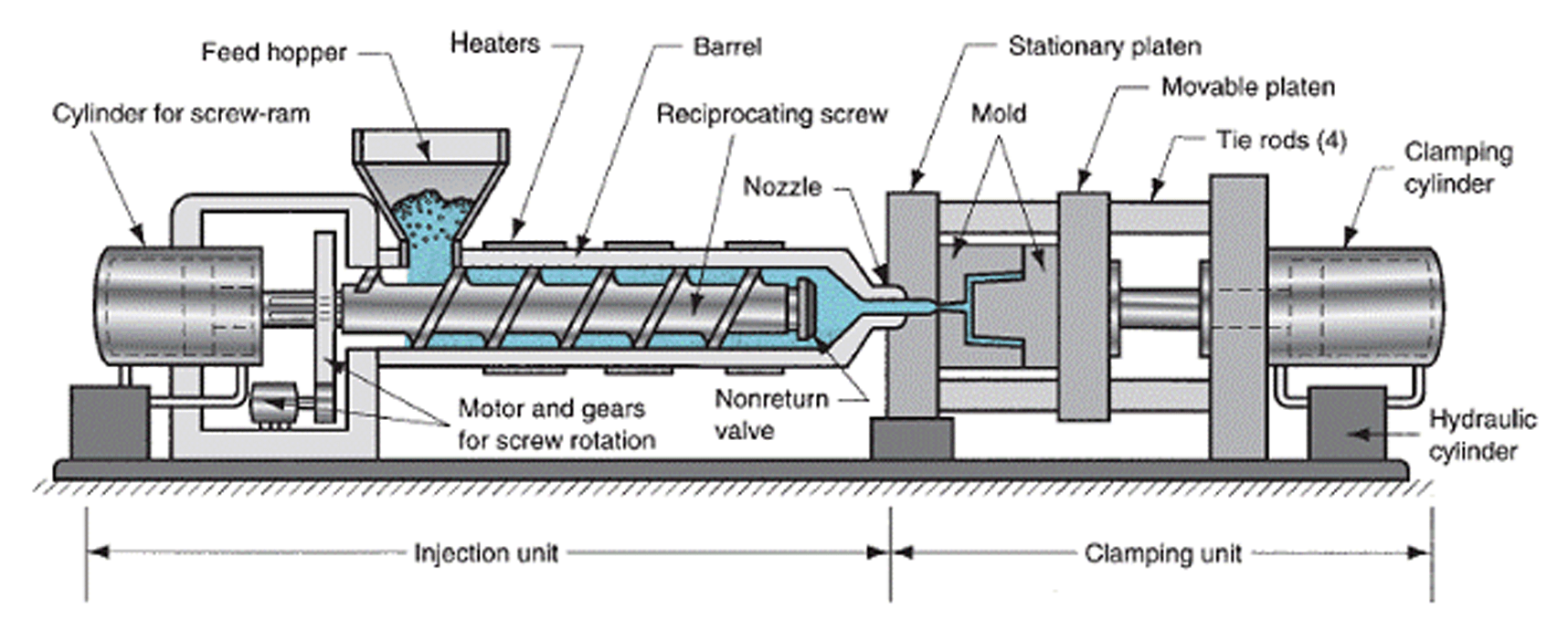

Injection molding machines, also known as presses, consist of a material hopper, an injection ram or screw-type plunger, and a heating unit. The molds are clamped to the platen of the molding machine, where plastic is injected through the sprue orifice to create injection molds.

Presses are rated by tonnage, which is the calculation of the amount of clamping force that the machine can exert. This force keeps the mold closed during the injection molding process. Tonnage can vary from less than 5 tons to 6000 tons, with the higher figures used in comparatively few manufacturing operations. The total clamp force needed is determined by the projected area of the custom part being molded. This projected area is multiplied by a clamp force of from 2 to 8 tons for each square inch of the projected areas. As a rule of thumb, 4 or 5 tons/in can be used for most injection molded products. If the plastic material is very stiff, it will require more injection pressure to fill the mold, thus more clamp tonnage is needed to hold the mold closed. The required force can also be determined by the material used and the size of the part, larger plastic parts require higher clamping force.

Today, electric presses are taking over the typical hydraulic injection molding machines. Companies who produce injection molds prefer them as they offer 80% less energy consumption and nearly 100% repeatability, by utilizing electric servo motors. While the cost of an electric molding machine is typically 30% higher than a hydraulic press, higher demand for injection molds is closing the gap on cost. It is estimated that in the next 20 years hydraulic molding machines will be a thing of the past, as more molding companies are making the switch to stay competitive.

We have 80-3000tons plastic injection machines, we can meet no matter how small and how big sizes fully for the customers, we can provide you the parts in 10 days or less.

How Does Injection Moulding Work?

Material granules for the part is fed via a hopper into a heated barrel, melted using heater bands and the frictional action of a reciprocating screw barrel. The plastic is then injection through a nozzle into a mould cavity where it cools and hardens to the configuration of the cavity. The mould tool is mounted on a moveable platen – when the part has solidified, the platen opens and the part is ejected out using ejector pins.

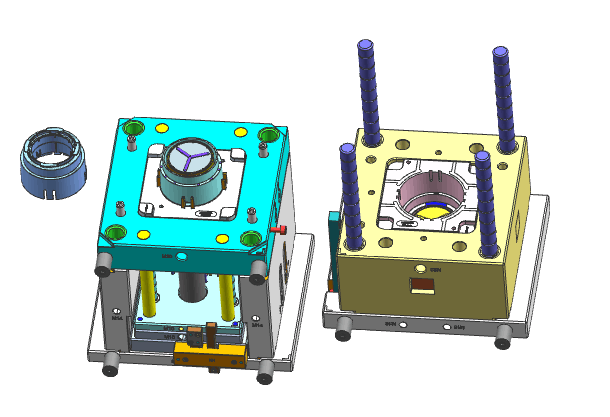

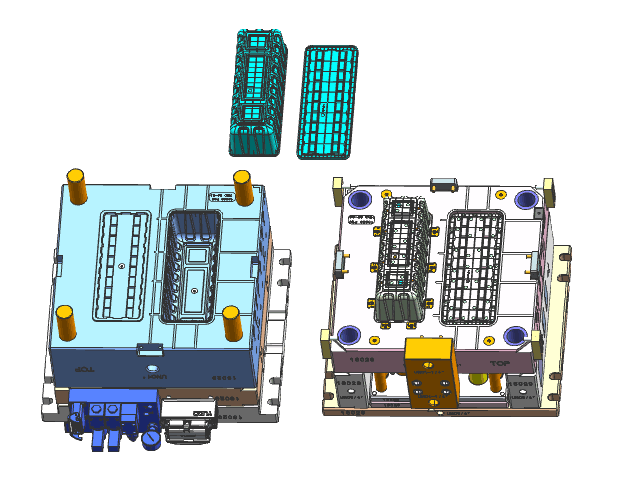

After a product is designed, usually by an industrial designer or an engineer, moulds are made by a mouldmaker (or toolmaker) from metal, usually either steel or aluminum, and precision-machined to form the features of the desired part.

Injection Molding Cycle

The sequence of events during the injection molding of a plastic part is called the injection molding cycle. The cycle begins when the mold closes, followed by the injection of the polymer into the mold cavity. Once the cavity is filled, a holding pressure is maintained to compensate for material shrinkage. In the next step, the screw turns, feeding the next shot to the front screw. This causes the screw to retract as the next shot is prepared. Once the part is sufficiently cool, the mold opens and the injection molded part is ejected. Molding companies typically use the formula below to determine a cycle time of injection molds.

Total time = 2M + T + C + E

Where:

(2M) = Twice the Mold Open/Close Time

(T) = Injection Time (S/F)

(C) = Cooling Time

(E) = Ejection Time (E)

(S) = Mold Size (in3)

(F) = Flow Rate (in3/min)

The total cycle time can be calculated using tcycle = tclosing + tcooling + tejection

The closing and ejection times of injection molded parts can last from a fraction of a second to a few minutes, depending on the size of the mold and machine. The cooling times, which dominate the process, depend on the maximum thickness of the part.

Cost

The cost of manufacturing injection molds depends on a very large set of factors ranging from number of cavities, size of the parts (and therefore the mold), complexity of the pieces, expected tool longevity, surface finishes and many others. The initial cost is great, however the piece part cost is low, so with greater quantities the overall price decreases. With global competition, companies with an ISO-Quality system usually will have better pricing as they have streamed lined their process and produce less defects. Mold Cost Guidline.

Different cavities of the mold, different unit price of the part, of course, mold cost also different.

More cavities of the molds, more cost would be higher, but the unit price of the part will be more cheaper.

Sigle Cavity (1*1)

Two Cavities (1*2)

Four Cavities (1*4)