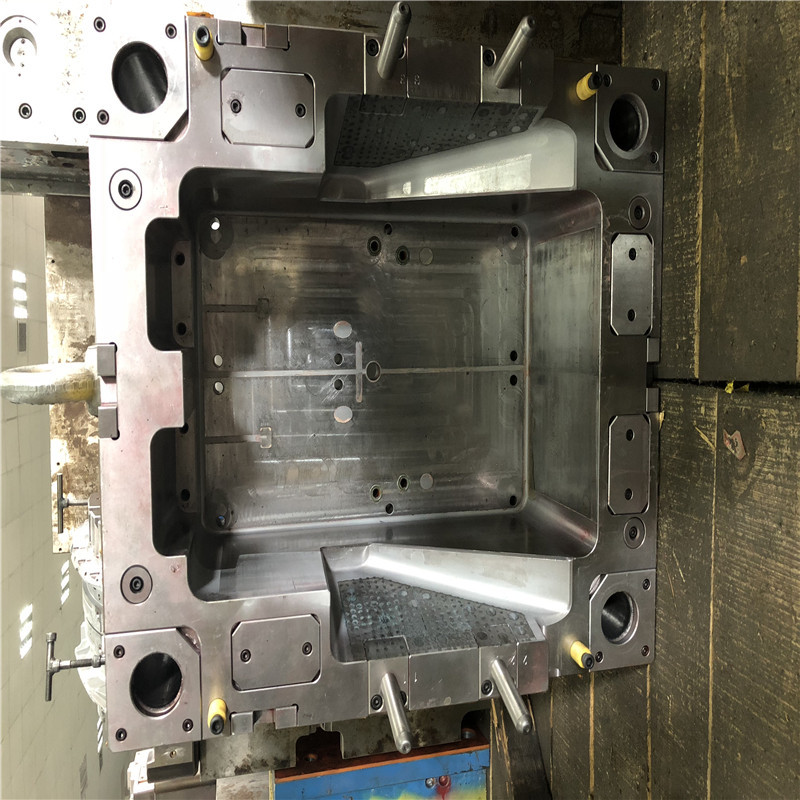

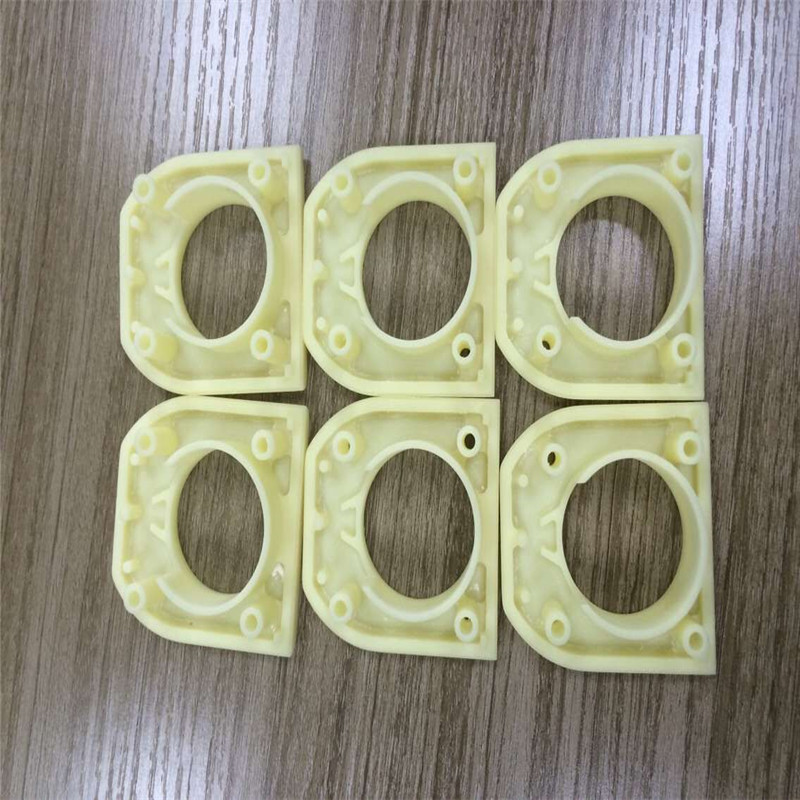

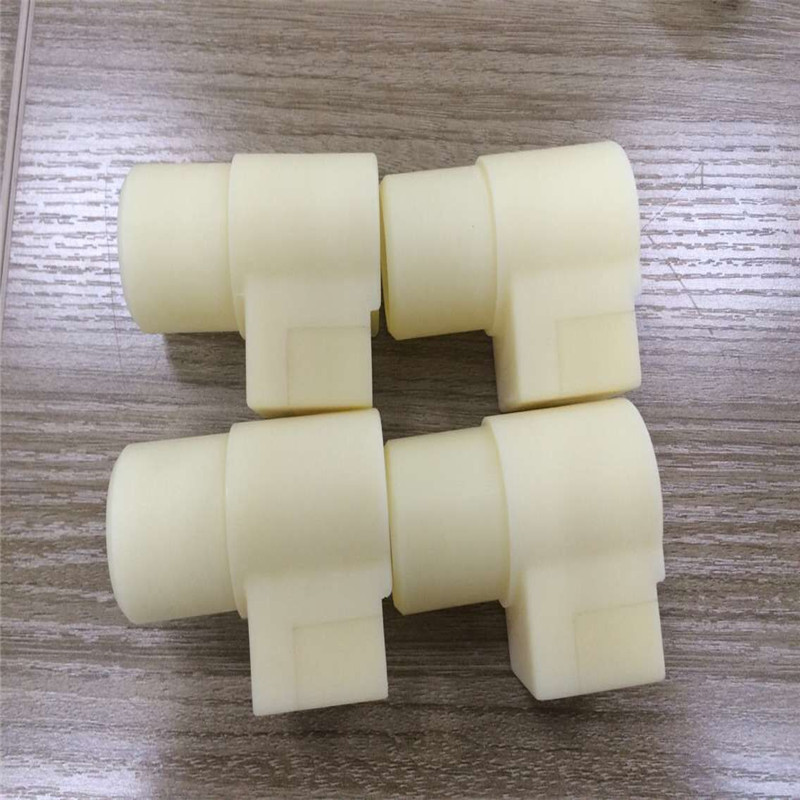

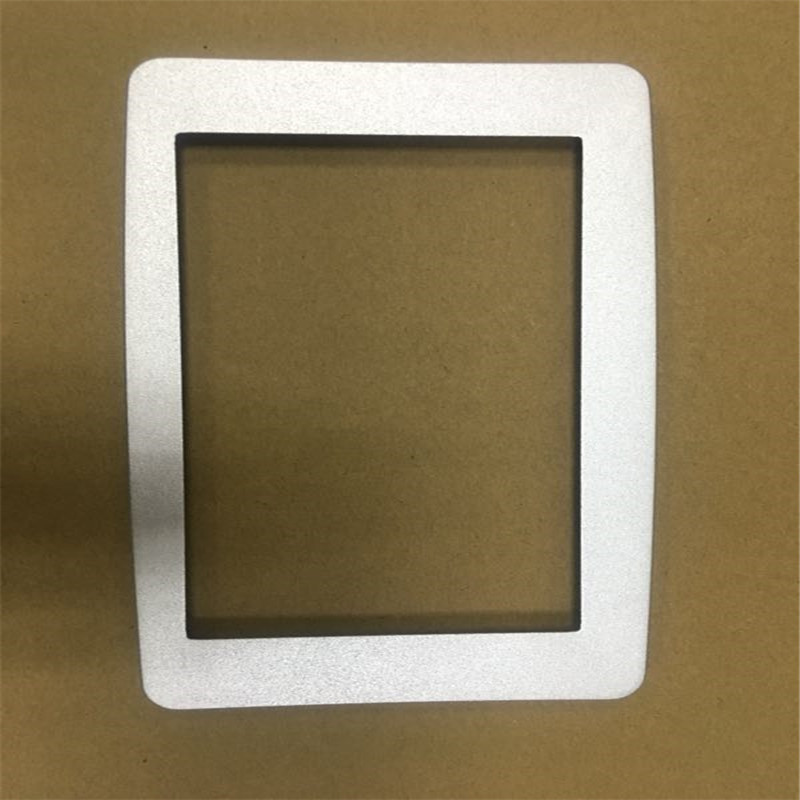

plastic injection mold tooling medical equipments prototype

- Model

- LX-M0014

Item specifics

- Products name

- medical equipments prototype

- Mold Type

- Plastic injection mold

- Mold Material

- 45#,P20 steel, 718, 2738, H13, NAK80, 2344, 2343, S136, etc .

- Design software

- CAD

- Mould Standard

- HASCO, DME, MISUMI, JIS, LKM, etc.

- Gate type

- Side Gate, Sub Gate, Direct Gate, Hook Gate, Pin Point Gate, etc.

- Runner type

- Cold Runner or Hot Runner

- Cavity

- both single and multi cavities available

- Suface treatment

- Polish, Etched, Texture, Heat treatment and Nitriding

- Mold life

- 45#:50,000 to 100,000 shots;718: 200,000 to 300,000 shots.H13: 300,000 to 500,000 shots

Review

Description

Mold Material | 45#,P20 steel, 718, 2738, H13, |

Mold Type | Plastic Injection Molding |

Product Material | ABS,PA,PA66+GF,POM,PC,PP,PET,TPE,PVC,HDPE, PMMA, PU, PAG,etc |

Mold Standard | HASCO, DME, MISUMI, JIS, LKM, etc. |

Mold Tooling Equipment | Lathe,Milling,Grinder,Drill,CNC,EDM, |

Injection Mold Machine | 80T to 2800T |

Product Weight | 50-20000g |

GateType | Side Gate, Sub Gate, Direct Gate, |

Runner Type | Cold Runner or Hot Runner |

Cavity | Single or Multi cavities |

Treatment | Heat treatment and Nitriding,polish ect. |

Mold Life | 45#:50,000 to 100,000 shots |

P20:100,000 to 200,000 shots | |

718: 200,000 to 300,000 shots | |

H13: 300,000 to 500,000 shots | |

Lead Time | Generally mold making will take around 30 days |

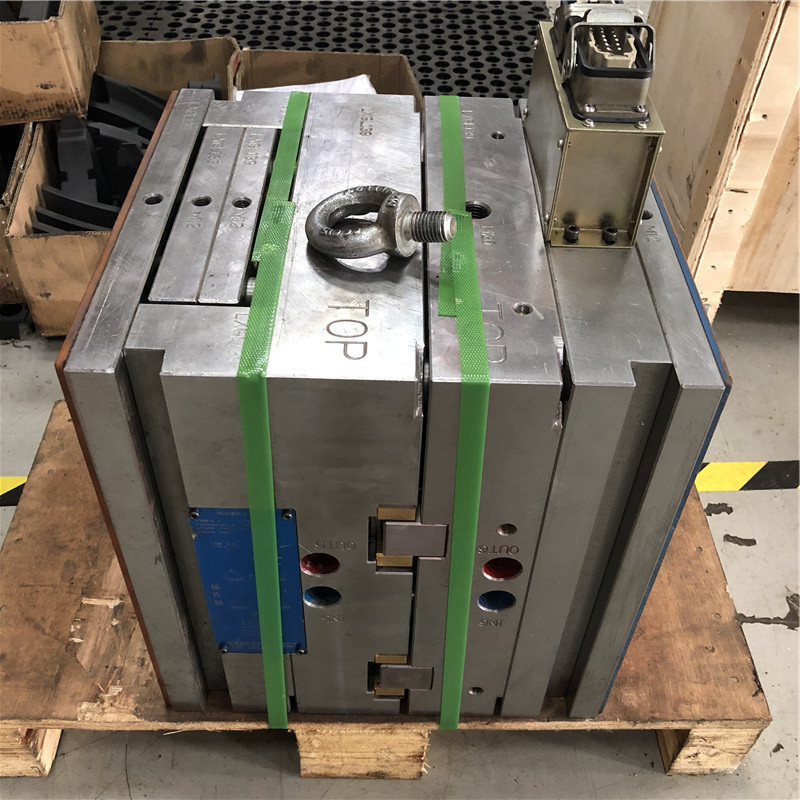

Package | Wooden packing box for molds |

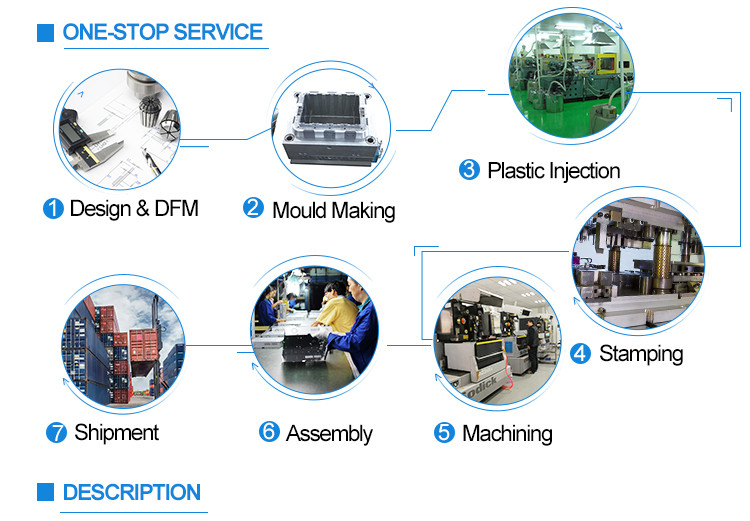

Tooling Developing Procedure:

1.Quotation: We need your require clearly

2.Negotiation: Material, cavity, price, delivery time, payment term, etc.

3.Order: According your own design or choice our design

4.DFMEA: Deign failure mold & Effect analysis to reduce risk

5.Mold design: 2D/3D drawing

6.Cutting Tooling Notice: After customer approve the mould design will start making mould

7.Weekly Report: We will update the mold schedule every week

8.Sample Confirm: Send you sample for conform it, if not satisfied by customer. We modify mould.

9.Delivery Mold: Delivery mould after customer approve sample and arrange shipment.